I also looked into inspections and registration. I don't want to install all the windows and weatherstripping yet, because it will only have to be removed again when the car is painted. However, I'd like to get several estimates on the paint job before I pay for painting, and the only practical way to do that is drive it there. . . Turns out that you don't need windows (or apparently a windshield) only wipers. Apparently, you don't need a speedometer either. . . Texas also has a 30 day temporary registration that allows you 30 days to get your inspection.

Being this close, reminded me that there are some repairs that needed to happen to systems I'd already installed.

One of these was the clutch master cylinder. The makeshift cap has continued to leak, so I had to buy a new one.

The only problem is that the only new ones I could find do not have the filler stem.

So I had to solder in the old one. . .I'm not sure what type of metal the new cap is made of, but it did NOT want to accept the solder. It took many tries to get it to take, but it finally did and has been reinstalled.

I'm glad I did.

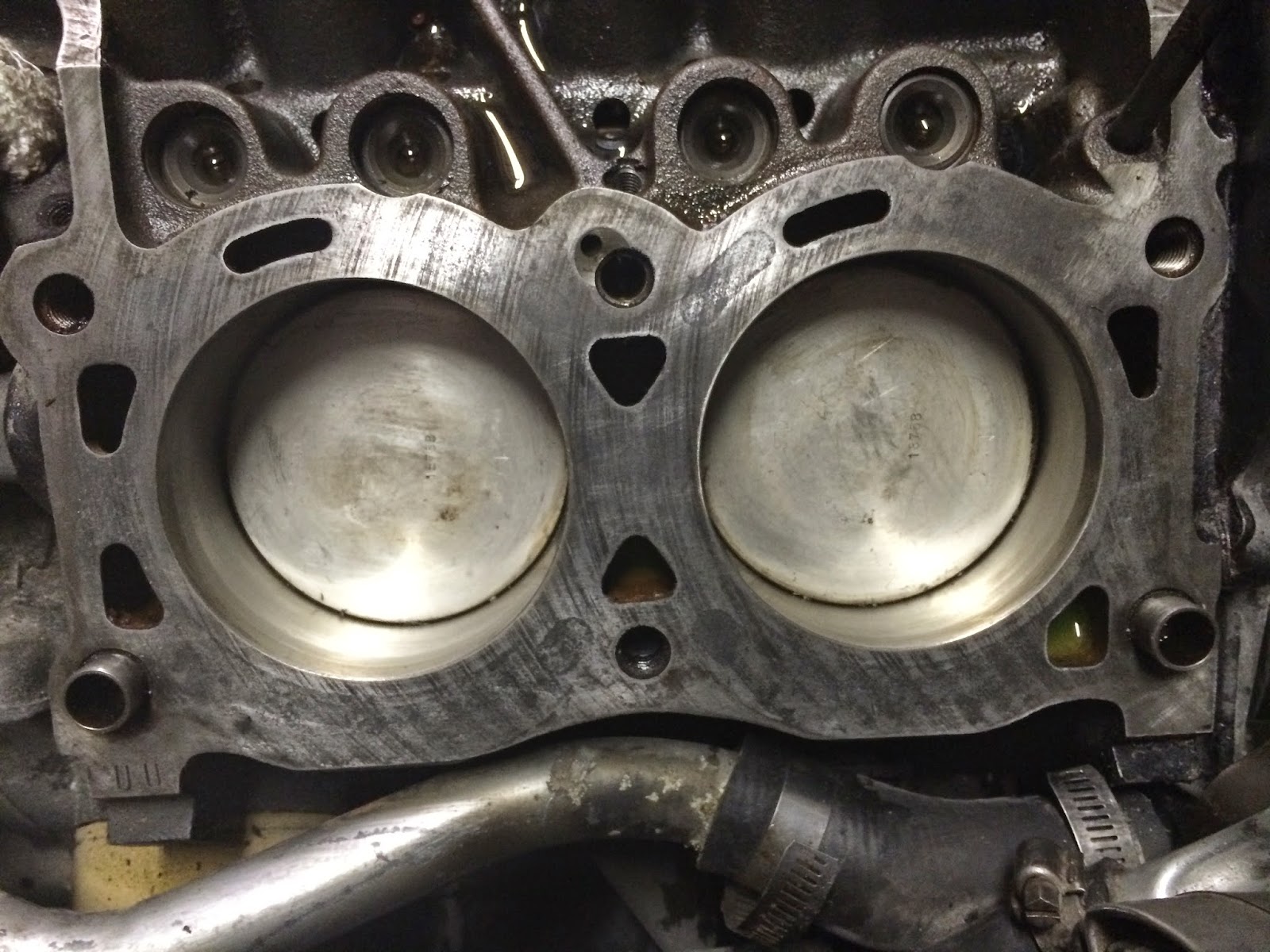

Take a look at the photos below and see if you can tell me what's wrong:

Did you notice there are three different hole patterns?

The new head gaskets are identical to the ones I installed last time. Which means that only a fraction of the coolant chambers are being filled, as the gasket was blocking some of them. Just as worisome is that fact that the head ports dont match up with the block ports. Nothing I can do about that, but I can adjust the new gaskets to allow as much flow as possible between the two. The gasket has an aluminum core, so I had to cut out the new openings with a dremel with router bit.

Incidentally, the same problem was true of the old manifold gasket. The gasket I installed last time intentionally blocked several of the ports. In hind sight, that is probably why it blew out - not because of the pressure, but because the manifold head warped slightly due to overheating.